From Concept to Creation

Laser Making Made Simple!

"I let mine sit for 6 months as I was scared to turn it on."

"I also let my laser sit for months due to fear."

"delivered and been sitting for a month... How do I learn? Where do I start?"

"I have only tried 1 thing, and it turned out horrible."

The quotes above are copied directly from Laser Support Forums where statements of this nature are not uncommon. I like inspirational quotes, these ones inspired me to start this Live Mentoring course for Laser Makers.

I get it!

As the proud owner of an awesome Laser machine, you are ready to press play and start making money asap! However, as it turns out there are a few other things to figure out first. Things like Vectors, Design Softwares, Materials, Settings, Production Methods, etc. etc.

I understand how overwhelming it all can seem at the start when you’re not even sure what questions to ask, or if the answers you get are the ones you need.

When I bought my Thunder Laser, I already had years of experience in Digital Design and Making. With this experience the path to operating my laser at a professional level was straightfoward, but, what if you are a new laser owner without these skills yet?

I can help!

Personally, I think the most efficient way to learn is from a Real Person who already has the desired knowledge & skills. I ask endless questions specfic to my requirements to gain a solid understanding of the process, excactly the thing you CAN’T do with pre-packaged video courses.

But what if there is a way to fast track your learning, in a relaxed, laid-back environment where questions are encouraged and new insights are welcome? A course customized to your individual needs and existing skill level? That is exactly what I’m offering !

Hello, I’m Ron Crown, accomplished creative professional with a rich background in Design and Making.

My career as an Animator has given me a strong sense of Design and the opportunity to be immersed in Digital Art Software from the beginning.

Ten years operating a CNC based Design & Make company has developed my technical proficiency and fluency in CAD/CAM software.

My time as an instructor at top-tier institutions has provided me the tools to put it all together in a simple, direct approach to help others become successful Makers.

How does it work?

Simple. We get together live in a video meeting, you ask questions, I provide answers along with demonstrations and examples. Repeat as needed until uncertainty becomes confidence.

Over the course of four sessions (approx. 12hrs) we’ll complete a Lesson Plan designed to cover the fundamentals of Laser Making from concept to creation. After the course you will continue your Maker journey with full troubleshooting support (4hrs max), plus, all sessions are recorded for your convenient review.

Process is the main focus!

Real success doesn’t come from just knowing “what button to push when”, it comes from gaining an understanding of the overall process and why the button exists in the first place.

Understanding the process it’s how you become confident enough to try new things and learn from your own mistakes. Even if you aren’t invloved in all steps yourself, knowing what they are and how they fit in the workflow is vital, it’s how you know what questions to ask and what answers fit.

Whether you plan on “cutting out thousands of widgets” or “making real your grandest creative ideas”, the process will follow this basic workflow. The Live Mentoring course follows this same process for a logical step by step approach.

1 - Concept

What will you make?

As simple as a well formed idea or as complex as a fully realized image created with your favorite design software this becomes your foundation to build on.

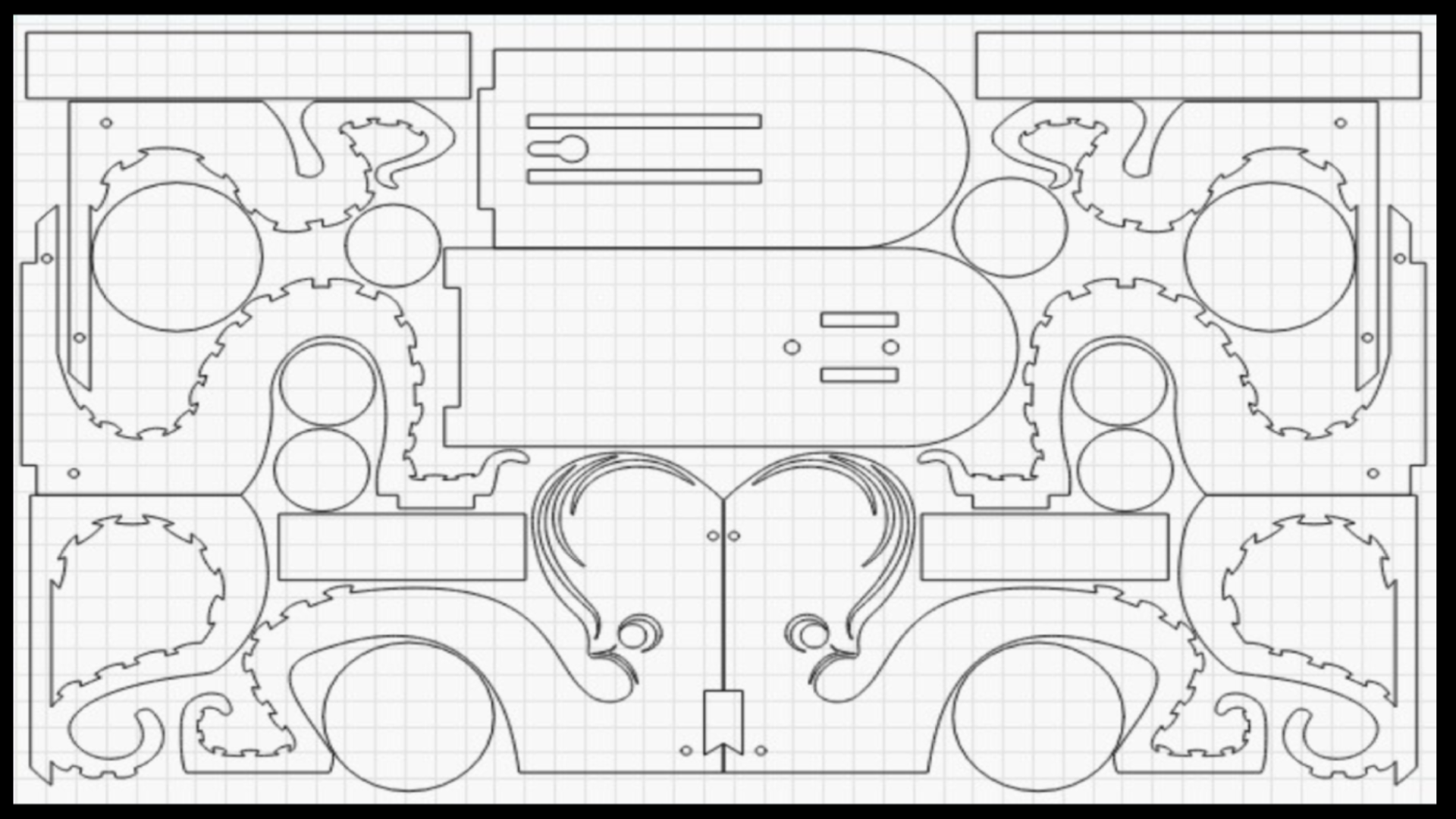

2 - CAD Design

How will you make it?

Design the precise details of your project, with final dimensions, materials, assembly/finishing techniques and nesting for efficient lasering.

3 - Engraving & Cutting

Making it!

Finalize the layering, prepare the materials, set up the laser, run tests to work out the best settings and if needed create jigs for production runs.

4 - Assemble and Finish

Putting it all together!

Some projects come off the laser finished and ready for shipping, many others require detailed assembly and finishing techniques to be applied.

Of course, each project has many variables, and each of these steps can contain many more steps. The workflow above is a general overview of the knowledge & skills required to run your laser professionally and create a successful business.

Ready to learn more? We should talk.

Click the button below, fill out the form, receive access to my calendar and then pick a time that works best for you.

During this initial, no commitment, meeting, I’d love to learn more about you, your creative ideas and current skill level. We’ll talk about your business goals and discuss the types of support that best fits your needs.

If you decide to learn with me, we’ll also discuss times and dates to work through the course.

Are you ready to elevate your business and become a laser expert? You’ll thank yourself in about 12 hours!